Turret Unit of Over Wrapping Machine

Turret Unit of Over Wrapping Machine Specification

- Application

- Wrapping and Overwrapping Packaging

- Power Supply

- Single Phase

- Usage

- Suitable for use in automatic overwrapping machines

- Noise Level

- <70 dB

- Type

- Turret Unit for Over Wrapping Machine

- Material

- Stainless Steel

- Feature

- Robust Design, Corrosion Resistant

- Auxiliary Packaging Machine Type

- Other

- Capacity

- Up to 60 packs/min

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Power

- 2.5 kW

- Weight (kg)

- Approx. 55 kg

- Dimension (L*W*H)

- 450 x 320 x 700 mm

- Color

- Silver (Metallic)

- Sealing Type

- Heat Sealing

Turret Unit of Over Wrapping Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 150 Pieces Per Week

- Delivery Time

- 15-20 Days

- Packaging Details

- wooden boxes

- Main Domestic Market

- All India

About Turret Unit of Over Wrapping Machine

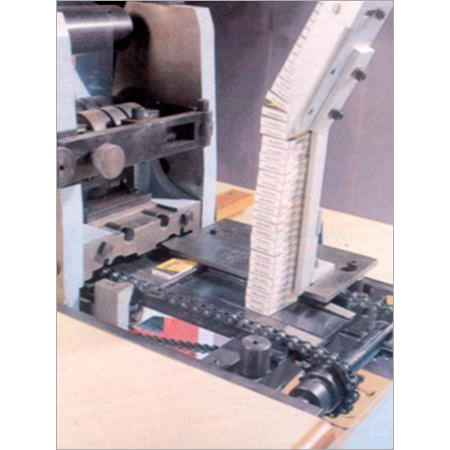

Turret Unit

Blessed and supported by the team of adroit professionals, our company is considered as one of the eminent manufacturers and exporters of Turret Unit. At our production unit, we have manufactured them as per the norms and standards set by the regulatory bodies. Efficient in performance, our Turret Unit has a lift capacity of 181kg and is hugely demanded in the national and international market. Available at market leading prices, our gamut of Turret Unit is acknowledged for its high operational fluency, longer working life, corrosion and rust proof surface finish.

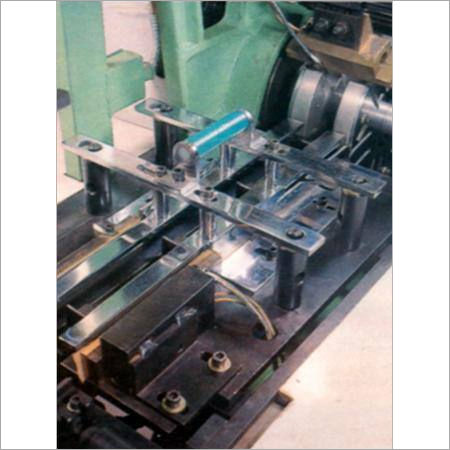

Advanced Automation and Control

Equipped with a PLC control system and computerized features, the Turret Unit ensures seamless integration into automatic overwrapping machines. Its electric drive simplifies operation and enhances reliability, reducing manual intervention during high-speed packaging tasks.

Durability and Corrosion Resistance

Constructed from premium stainless steel, this turret unit boasts excellent corrosion resistance and a robust design. Its durable build allows consistent operation in demanding packaging environments, significantly extending service life and maintaining performance quality.

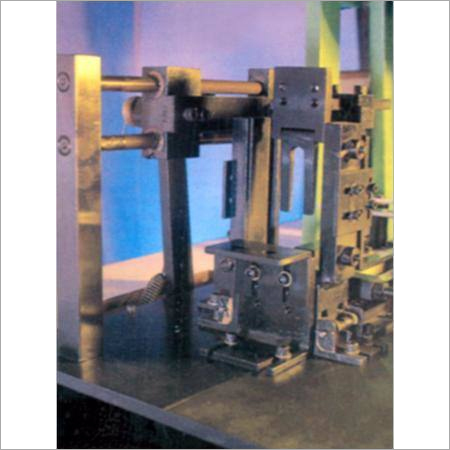

Optimized Performance for Packaging

With a capacity of up to 60 packs per minute and efficient heat sealing, the unit is engineered to maximize productivity. Its compact dimensions and low noise output facilitate installation in various production setups, ensuring smooth, uninterrupted packaging processes.

FAQs of Turret Unit of Over Wrapping Machine:

Q: How does the PLC control system enhance the performance of the turret unit in overwrapping machines?

A: The PLC control system provides precise and automated operation, enabling accurate wrapping and heat sealing. It minimizes errors, increases packaging speed, and ensures consistent output, improving overall efficiency in the overwrapping process.Q: What materials are used in the turret unit and why are they important?

A: The turret unit is made from high-grade stainless steel, chosen for its exceptional resistance to corrosion and robust structural strength. This material ensures reliability and longevity, even in environments with high moisture or packaging activity.Q: When should the turret unit be serviced to maintain optimal performance?

A: Regular maintenance should be performed following the manufacturers guidelines, typically after a set number of operating hours or packs produced. Periodic inspections and cleaning help sustain peak performance and minimize unexpected downtime.Q: Where is the turret unit best installed within an overwrapping machine setup?

A: The turret unit is designed for placement within automatic overwrapping machines, ideally in areas that allow easy access for monitoring and maintenance, and where its compact size fits seamlessly into the existing production configuration.Q: What is the process for installing the turret unit in an overwrapping machine?

A: Installation involves securely positioning the unit within the machine framework, connecting the electric drive and PLC controls, and configuring the computerized interface for automated operation. Professional installation is recommended for optimal integration.Q: How does the unit benefit the packaging operation compared to manual alternatives?

A: By automating the wrapping and heat sealing processes, the turret unit significantly boosts speed, consistency, and quality, while reducing labor costs and operator fatigue. Its computerized and PLC-controlled features ensure reliable, repeatable results in high-volume environments.Q: Can the turret unit handle different pack sizes and types of wrapping materials?

A: The unit supports a variety of pack sizes and wrapping materials compatible with automatic overwrapping machines, offering flexibility for diverse packaging requirements. Adjustments and settings can be easily managed via its computerized controls.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Packaging Machine Units Category

Manual Feeder Unit of Over Wrapping Machine

Price Range 900000.00 - 2500000.00 INR

Minimum Order Quantity : 1 Piece

Color : Silver

Noise Level : Low

Control System : Other, Mechanical

Type : Other, Manual Feeder Unit

Packaging Machine Delivery Unit

Price Range 900000.00 - 2500000.00 INR

Minimum Order Quantity : 1 Piece

Color : Other, Silver / Metallic

Noise Level : Less than 75 dB

Control System : Other, PLC based

Type : Other, Delivery Unit

Collator Unit of Over Wrapping Machine

Price Range 900000.00 - 2500000.00 INR

Minimum Order Quantity : 1 Piece

Color : Other, Silver/Grey

Noise Level : <75 dB

Control System : Other, PLC based electronic panel

Type : Other, Collator Unit

Bobbin and Electrical Unit of Over Wrapping Machine

Price Range 900000.00 - 2500000.00 INR

Minimum Order Quantity : 1 Piece

Color : Other, Silver and blue

Noise Level : Low noise

Control System : Other, Advanced electronic controller

Type : Other, Bobbin and Electrical Unit

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS