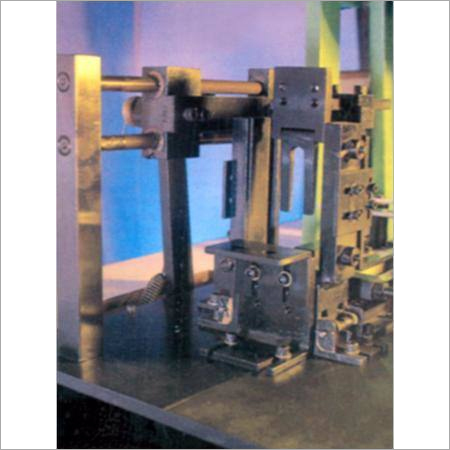

Collator Unit of Over Wrapping Machine

Collator Unit of Over Wrapping Machine Specification

- Usage

- Integrated in over wrapping lines to feed wrapped units in correct orientation

- Noise Level

- <75 dB

- Application

- Grouping and aligning packs for overwrapping

- Power Supply

- Single/Three Phase

- Type

- Collator Unit

- Feature

- Accurate collation, easy changeover, FIFO operation

- Auxiliary Packaging Machine Type

- Other

- Capacity

- Up to 60 packs/min (subject to pack and film type)

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC based electronic panel

- Power

- 1.5 kW

- Voltage

- 220/380 V, 50/60 Hz

- Weight (kg)

- Approx. 220 kg

- Dimension (L*W*H)

- 1200 mm x 800 mm x 1500 mm (approx.)

- Color

- Silver/Grey

Collator Unit of Over Wrapping Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 150 Pieces Per Week

- Delivery Time

- 15-20 Days

- Packaging Details

- wooden boxes

- Main Domestic Market

- All India

About Collator Unit of Over Wrapping Machine

Collator Unit

Judicial mix of men and machinery, our company has been able to mark its strong presence in the market as one of the well equipped manufacturers and exporters of Collator Unit. We employ optimum quality raw materials and advanced technology in the manufacturing process. Our team of quality inspectors examines this unit on various quality parameters which is predefined by the industry. This Collator Unit is useful in printing papers and are widely appreciated due to its rugged design and user friendly features.

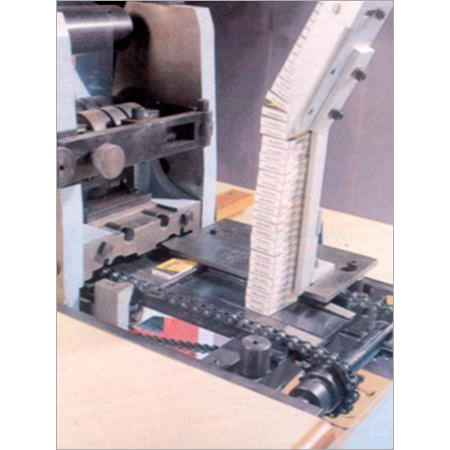

Efficient Grouping and Alignment

The collator unit automates the grouping and alignment of packs, optimizing the workflow for overwrapping lines. With its advanced computerized control and FIFO operation, it ensures every pack is oriented correctly, reducing product mishandling and maximizing throughput efficiency.

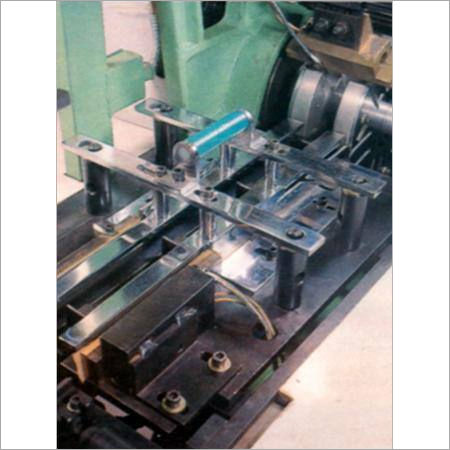

Advanced Control System

Utilizing a PLC-based electronic panel, this unit delivers precise and reliable control over the collation process. The user-friendly interface supports quick changeovers, making adaptation to different pack and film types seamless, while maintaining stable performance.

Designed for Seamless Integration

Built to integrate effortlessly with any standard over wrapping machine, the collator unit supports both single and three-phase power supplies. Its compact design and low noise level make it well suited for varied industrial environments, ensuring operational continuity.

FAQs of Collator Unit of Over Wrapping Machine:

Q: How does the collator unit improve the overwrapping process?

A: The collator unit enhances the overwrapping process by accurately grouping and aligning packs before they enter the wrapping stage. This ensures consistent orientation, reduces product handling errors, and streamlines the workflow, thereby increasing efficiency.Q: What is the maximum capacity of this collator unit?

A: The unit can process up to 60 packs per minute, although actual capacity may vary according to the type and size of the packs as well as the film material used.Q: When should I consider using a collator unit in my packaging line?

A: A collator unit is recommended when you need to group multiple packs and ensure they are fed in the correct orientation into an overwrapping machine. It is especially beneficial for high-volume packaging environments seeking consistent alignment and increased automation.Q: Where can this collator unit be installed?

A: The unit is designed for integration within over wrapping lines at manufacturing and packaging facilities. Its compact dimensions allow flexible placement in various industrial setups.Q: What is the control mechanism used in the collator unit?

A: The collator unit is equipped with a PLC-based electronic control panel that allows computerized operation, supporting accurate collation and easy changeover between products.Q: How does the FIFO feature benefit my operations?

A: The FIFO (First-In-First-Out) operation ensures that packs are processed in the order they arrive, enhancing traceability and minimizing potential confusion or product mix-ups in the packaging line.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Packaging Machine Units Category

Manual Feeder Unit of Over Wrapping Machine

Price Range 900000.00 - 2500000.00 INR

Minimum Order Quantity : 1 Piece

Power Supply : Manual Operation, No Power Supply Needed

Feature : Other, Easy operation, sturdy construction

Dimension (L*W*H) : 800 mm x 300 mm x 900 mm

Application : Feeding products to over wrapping machine

Packaging Machine Delivery Unit

Price Range 900000.00 - 2500000.00 INR

Minimum Order Quantity : 1 Piece

Power Supply : Single Phase AC

Feature : Other, High efficiency, robust construction

Dimension (L*W*H) : 1800 x 450 x 900 mm

Application : Packaging Line Integration

Turret Unit of Over Wrapping Machine

Price Range 900000.00 - 2500000.00 INR

Minimum Order Quantity : 1 Piece

Power Supply : Single Phase

Feature : Other, Robust Design, Corrosion Resistant

Dimension (L*W*H) : 450 x 320 x 700 mm

Application : Wrapping and Overwrapping Packaging

Bobbin and Electrical Unit of Over Wrapping Machine

Price Range 900000.00 - 2500000.00 INR

Minimum Order Quantity : 1 Piece

Power Supply : AC powered

Feature : Other, Smooth operation, corrosion resistant

Dimension (L*W*H) : 320 x 220 x 190 mm (typical)

Application : Over wrapping machine spare/replacement unit

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS